Thunder Laser successfull…

Release Time:2016/05/19 troubleshooting Browsing Times:2151

The problem is generally caused by two reason:

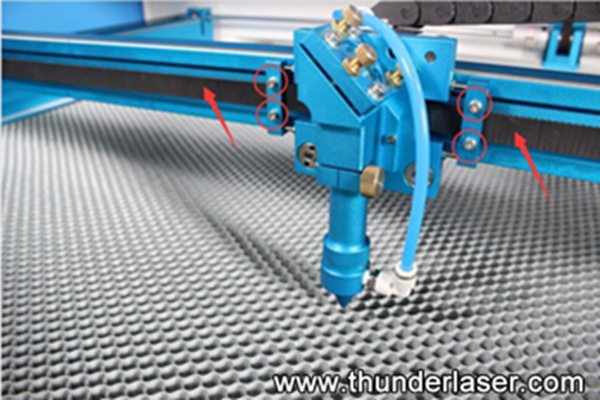

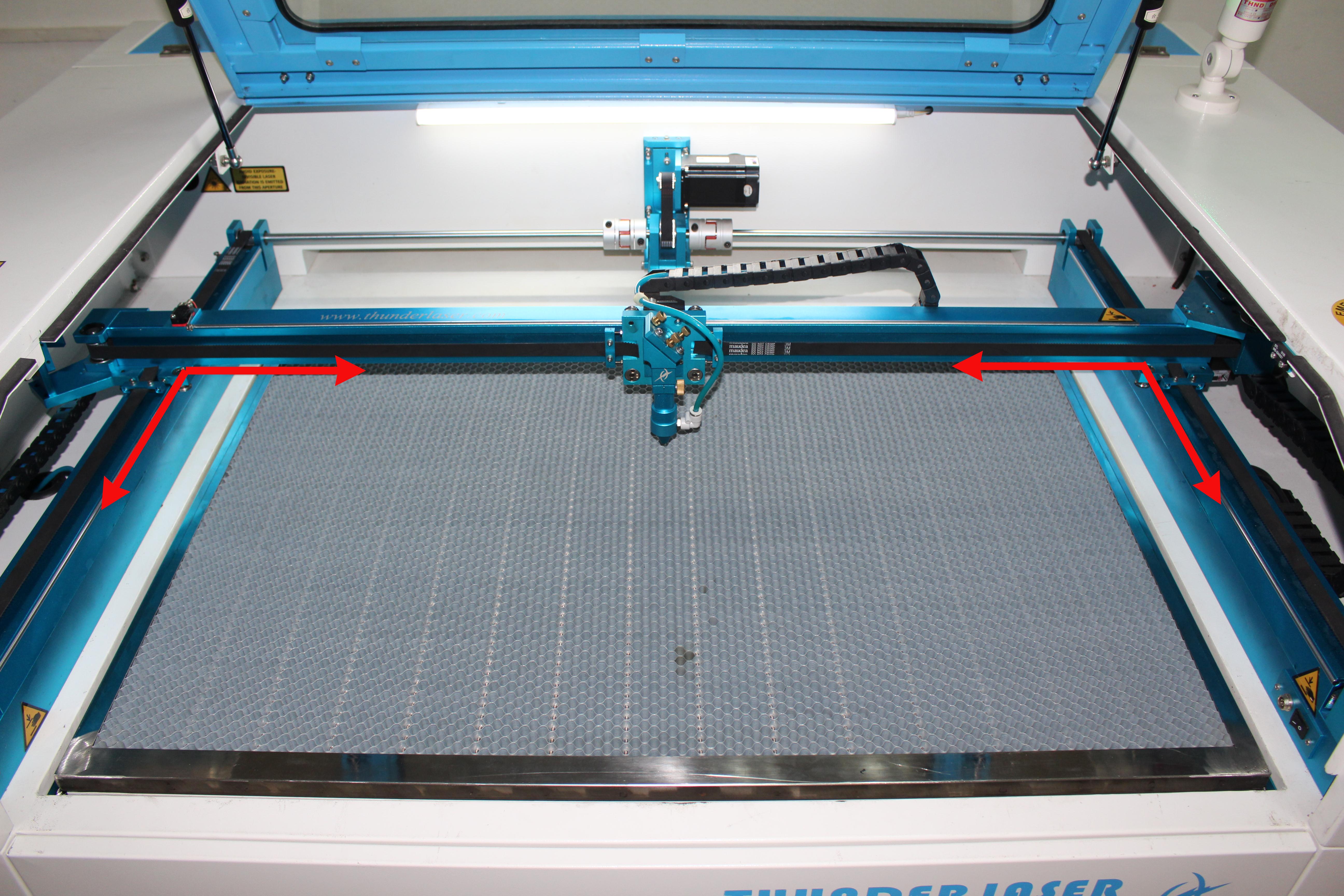

1. Belts of X axis and Y axis is loose:

① please check if X axis is loose

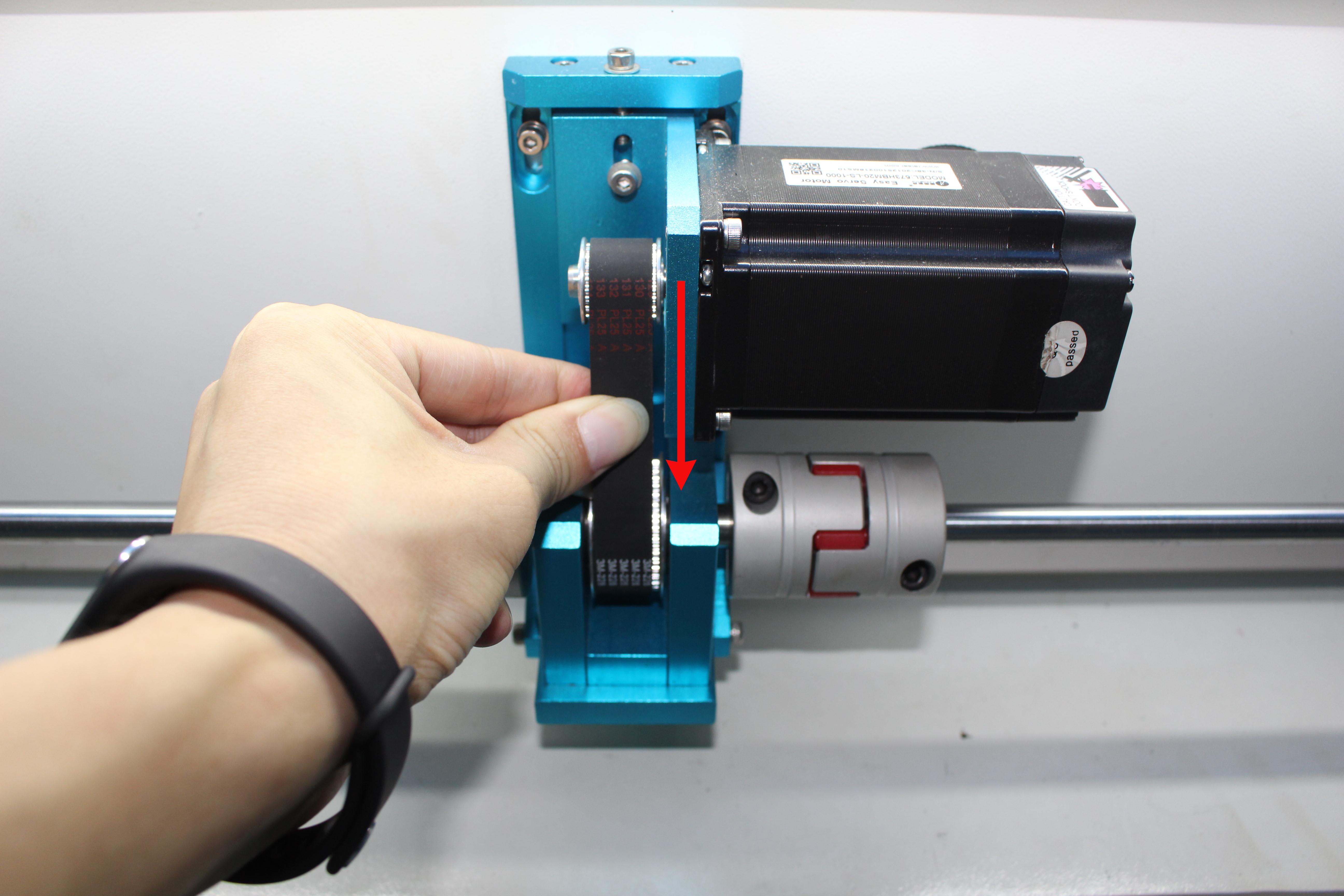

② please check if belt of Y axis is loose like below:

2. Caused by guiding rail of X axis not perpendicular with guide rails of Y axis

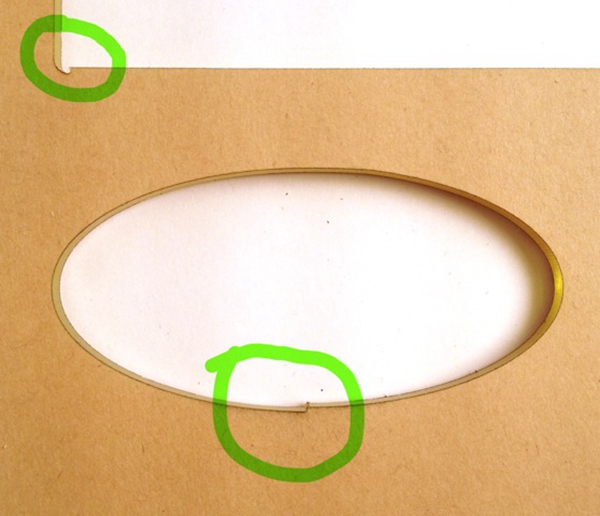

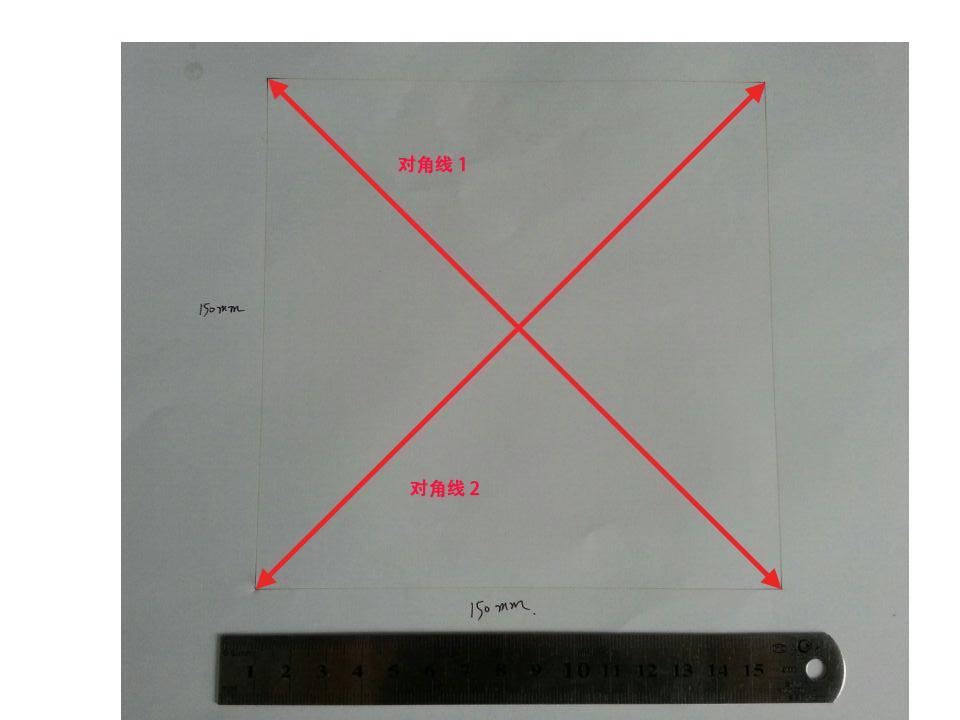

Please cut a foursquare, check if the two diagonal lines are equal.

Cut a foursquare of 150mm X 150mm, and then measure to see if the two diagonal lines are equal. Error value must be less than 0.5mm like below:

If diagonal line 1 is not equal to diagonal line 2 and the error value is more than 0.5mm, please mechanically adjust the X and Y axis guide rails to make them perpendicular, like below:

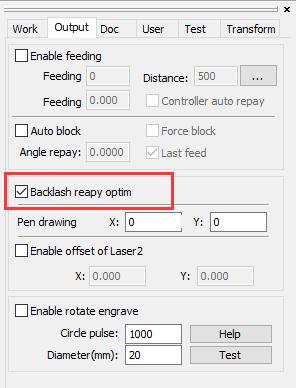

3. If the belts are not loose and the diagonal lines are equal or in the error control range, but the problem is still exist, please check the software like below:

Then redownload the file to laser machine and test again.

If the problem cannot be solved, please contact our tech team by email: tech@thunderlaser.com