Thunder Laser successfull…

Release Time:2016/12/07Browsing Times:1933

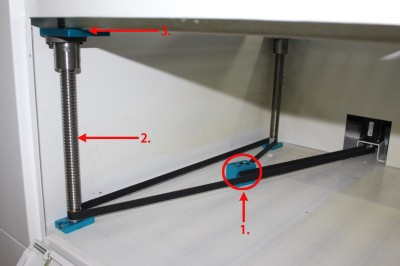

There are three cases. 1. Two sides of the working table are not of the same height. Turn off the whole machine power, manually pull one of the belts of Z axis so as to adjust the up and down of ...

Release Time:2016/12/06Browsing Times:1839

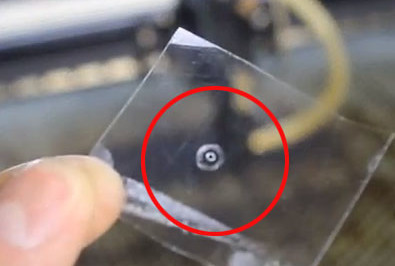

Some point of the same piece of materials cannot be cut through, why? This problem is mainly caused by following three reasons: 1. The cutting material is bent (not flat) or uneven density. 2. T...

Release Time:2016/11/29Browsing Times:1758

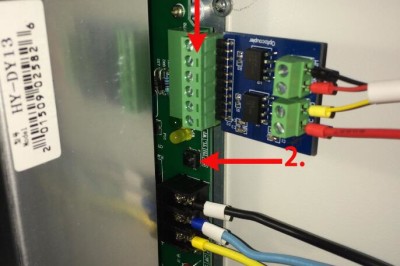

Following reasons cause the failure of laser working (has no laser beam) 1. Cooling system problem (includes water chiller) 2. Laser power supply (optical coupled isolator) or Laser tube 3. Wiri...

Release Time:2016/11/28Browsing Times:1870

1. Please check if the rotary switch is turned on,like below: PS: Turning to "O" off means all is normal. If it is "-", please turn off to “O” and press the reset on control panel. 2. if t...

Release Time:2016/11/23Browsing Times:2137

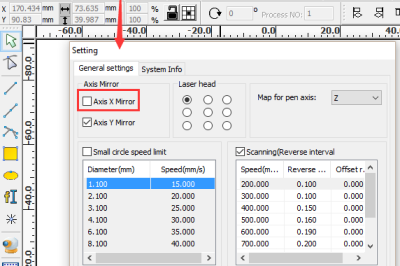

This problem may cause from improper setting of the software. Please start up the laser software RDWorksV8. And then click “Config” – “system setting” on the menu bar. This dialog box appears. ...

Release Time:2016/11/21Browsing Times:2270

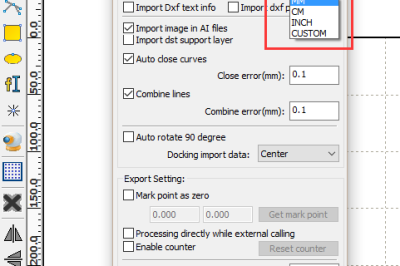

If the file being imported is DXF format, the problem may be caused by improper software setting. For example, the unit of the original DXF file is “inch”, but in RDWorks, the DXF unit is set as “...

Release Time:2016/11/17Browsing Times:2260

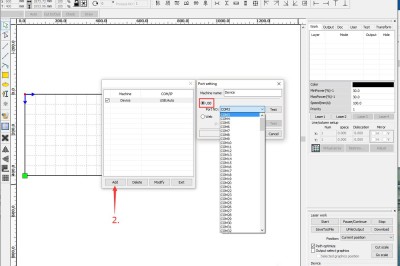

If there are several USB interfaces with your PC, it's able for one PC (laser software) to connect with several machines. But pc will does only communicate with one machine and sending the f...

Release Time:2016/11/11Browsing Times:3170

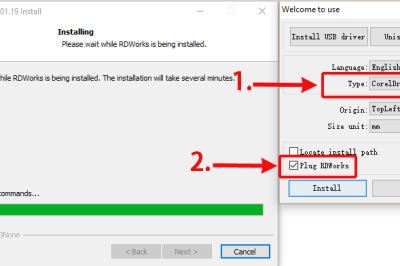

1. Firstly run CorelDraw and set the parameter following below instructions: 2. After that, close CorelDraw. Double click to open RDWorks installation program. Choose the type of CorelDraw_L...