Thunder Laser successfull…

| Laser System | NOVA 24 Class 1 | NOVA 35 Class 1 | NOVA 51 Class 1 | NOVA 63 Class 1 | ||

| Laser Tube Wattage | 40-60Watt | 80-130Watt | 100-130Watt | 100-150Watt | ||

| Work Area | 600x400mm(23.6″ x 15.7″) | 900x600mm(35.4″ x 23.6″) | 1300x900mm(51.2″x35.4″) | 1600x1000mm(63.0″x39.4″) | ||

| Max Part Size (WxLxH) | Front door closed | 700x530x170mm(27.6″ x 20.9″ x6.7″) |

1000x730x230mm(39.4″ x 28.7″ x9.0″) |

1400x1030x230mm(55.1″ x 40.6″ x9.0″) |

1700x1130x230mm(66.9″ x 44.5″ x9.0″) |

|

| Pass-through door | 700x∞x15mm(27.6″ x ∞” x 0.6″) |

1000x∞x20mm(39.4″ x ∞” x0.8″) |

1400x∞x20mm(55.1″ x ∞” x0.8″) |

1700x∞x20mm(66.9″ x ∞” x0.8″) |

||

| Table Size | 700x530mm(27.6″ x 20.9″) | 1000x730mm(39.4″ x 28.7″) | 1400x1030mm(55.1″ x40.6″) | 1700x1130mm(66.9″ x 44.5″) | ||

| Z Axis Height | 155mm(6.1″) | 230mm(9.1″) | 230mm(9.1″) | 230mm(9.1″) | ||

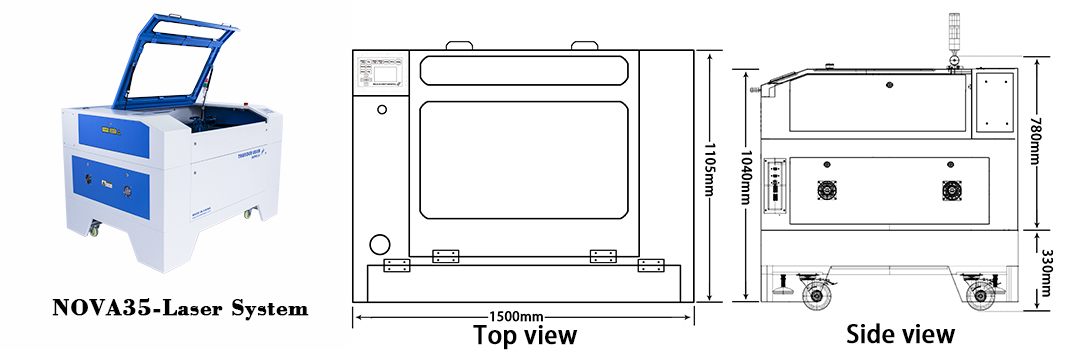

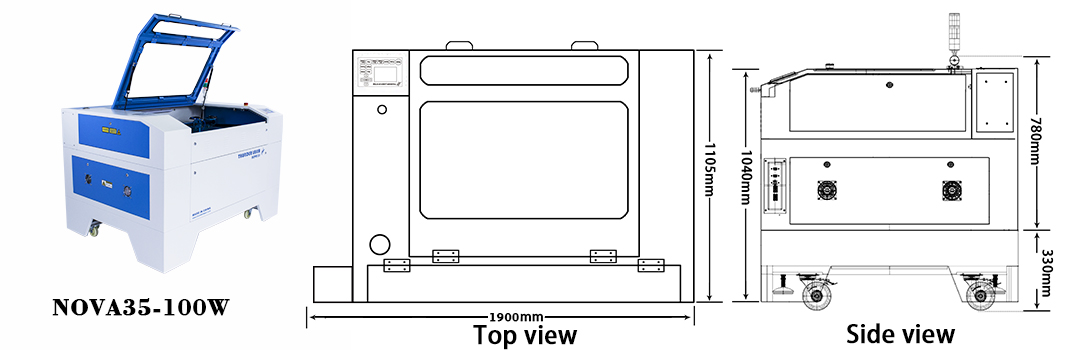

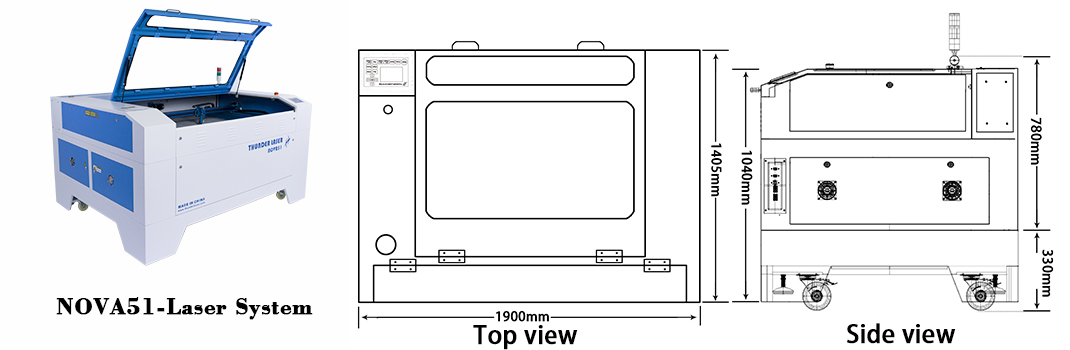

| Dimensions(WxDxH) | 1070x790x610mm(42.1″ x 31.1″ x24″) |

1500x1105x1040mm(59.1″ x 43.5″ x40.9″) |

1900x1405x1040mm(74.8″ x 55.3″ x40.9″) |

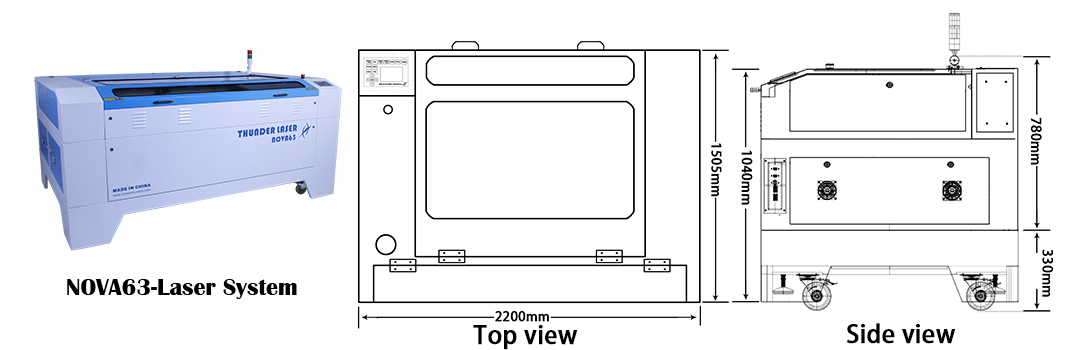

2200x1505x1040mm(86.6″ x 59.3″ x40.9″) |

||

| Net Weight | 130kgs(287lbs) | 310kgs(683lbs) | 430kgs(948lbs) | 470kgs(1036lbs) | ||

| Laser Type | Sealed Co2 Glass Laser Tube | |||||

| Cooling | Water Cooled | |||||

| Motion Control System | High-Speed Hybrid servo motor | |||||

| Maximum Speed | 1000mm/S(39.4 IPS) | |||||

| Speed and Power Control (engraving depth) | Computer or manually controlled speed and power from 0-100%. Vector color mapping sets speed and power settings using RGB color mapping. | |||||

| Operating Modes | Optimized raster, vector, and combined mode | |||||

| Resolution(DPI) | User controlled from 100 to 500DPI(standard laser head), up to 1000 DPI(HR head) | |||||

| Computer Interface | Ethernet and USB Connection | |||||

| Compatible Operating Systems | Windows XP/2000/Vista/7/8/10 | |||||

| Buffer Memory | 128MB Standard | |||||

| Display Panel | 3.5″ LCD panel showing current file, total working time, laser power, speed etc. | |||||

| Electrical Requirements | 110 to 240 volts, 50 or 60 Hz, single phase | |||||

| Ventilation System | Integral exhaust fan.There is 1 output port, 5.7″ (145 mm) in diameter in the rear of the case. | |||||

| Standard Features | Red dot pointer, Auto focus, Motorized table, Pass-through Door, Air Assist, Water pump ,Exhaust fan, HoneyComb Table, 2″ (50.8 mm) Focus Lens, Easily adjustable Home position, LCD Display,3D Engraving ,”No water” protection, Emergency stop, Maintenance mode, Open cover protection,Hybrid servo motor | |||||

| Optional Features | ||||||

| High Resolution Head | Increase the resolution up to 1000DPI | |||||

| Rotary Axis | Use to engrave on round items | |||||

| Water Chiller | Improve the cooling of laser tube | |||||

If your material is not in the below list, our Applications Team would be happy to assist you to test it.

| Materials | Engrave | Cut |

| Wood | √ | √ |

| Acrylic | √ | √ |

| Delrin |

√ |

√ |

| Cloth |

√ |

√ |

| Leather | √ | √ |

| Mat Board | √ | √ |

| Melamine |

√ |

√ |

| Paper | √ | √ |

| Mylar | √ | √ |

| Pressboard | √ | √ |

| Rubber | √ | √ |

| Wood Veneer | √ | √ |

| Fiberglass | √ | √ |

| Plastic | √ | √ |

| Cork | √ | √ |

| Corian | √ | √ |

| Twill | √ | √ |

| Anodized Aluminum | √ | X |

| Painted Metals | √ | X |

| Tile | √ | X |

| Glass | √ | X |

| Coated Metals | √ | X |

| Ceramics | √ | X |

| Marble | √ | X |

| Stainless Steel | * | X |

| Brass | * | X |

| Titanium | * | X |

| Bare Metal | * | X |

* means the laser cannot engrave directly, you will need the help of the “thermark spray”, you can visit www.thermark.com for more information.

https://www.thunderlaserthai.com/video/what-laser-cutter-can-create.html

https://www.thunderlaserthai.com/video/how-to-use-your-laser-machine.html

https://www.thunderlaserthai.com/video/how-to-use-your-laser-software.html

https://www.thunderlaserthai.com/video/how-to-use-your-laser-software.html